01 August 2022

How does Goma's expertise help in effective coconut processing?

Coconut processing is the process of converting coconuts into several usable items. The process comprises removing the hard shell, drying or grinding the coconut meat, and extracting oils or fluids.

This processing contributes to the production of coconut oil, milk, water, flour, and other delightful specialties.

The manufacturing of coconut products has increased tremendously all over the world, and so has coconut processing.

The consumption of coconut water has massively increased in the past decade The coconut products market size is estimated to reach $31.1 billion by 2026, registering a CAGR of 13.6% from 2019 to 2026.

Coconut-based products are gaining great importance due to their invigorating nature and are already entering the Indian market to give harsh competition to other milk and fruit-based beverages in the coming future.

The major coconut products in India include tender coconut water, coconut milk, coconut cream, coconut oil, Virgin coconut oil, desiccated coconut powder, spray dried coconut powder, Nata de cocoa, Coconut Neera, etc.

Tender coconut water is an excellent source of sugar, consists of minerals such as sodium, Phosphorus, potassium, calcium, and iron, and also includes substantial quantities of general vitamins.

Coconut water consumption helps with the following:

Hydration: Coconut water provides natural isotonic balance as its composition matches that of human blood.

Natural Salt: It contains natural salt that helps rejuvenate the body.

Skin Glow: Coconut water has special properties that give the skin a vibrant glow.

Improves Concentration: It also helps in heightening the concentration levels in a person

Some other coconut based products are:

Coconut milk & cream are excellent sources of fat, good quality protein, & sugar. It is used in the manufacturing of different foods and beverages.

Virgin Coconut Oil is said to be the “mother of all oils “and is extracted from fresh coconut milk without any heat or chemical treatment. It is rich in lauric acid and vitamin E.

Being non-greasy and non-straining, it is widely used in soaps, lotions, creams, and lip balms.

Desiccated coconut powder is a rich source of fat & protein. It is mainly used as an ancillary to grated coconut in food preparations such as curries, cakes, sweets, and chutneys.

It is manufactured from the coconut meat obtained during the extraction of coconut milk.

Coconut milk powder can be used instead of fresh coconut milk for the preparation of food and beverages in households and food productions.

Neera, also known as palm nectar, is rich in carbohydrates, mostly sugar minerals, and salt, which also contains ascorbic, nicotinic acid, and riboflavin.

Coconut processing method

Harvesting: Coconuts are harvested when they reach maturity. This requires climbing coconut trees or using tools to cut down ripe coconuts.

Husking: The coconut's outer husk is removed to reveal the hard shell below. This can be done either manually or with specific tools.

De-shelling: The hard shell split open to reveal the white coconut meat within. This phase can be completed using a variety of methods, including mechanical cracking and manual splitting.

Extracting Coconut Water: If wanted, coconut water can be extracted from young green coconuts. This is normally accomplished by drilling a hole in the coconut and emptying the water.

Grating or shredding: The coconut meat is next grated or shredded in preparation for further processing. This can be done manually or with mechanical grating machines.

Drying: The grated coconut meat is spread out to dry, either in the sun or with drying equipment. Drying reduces moisture content and extends the shelf life of coconuts.

Pressing or Collecting: Depending on the intended end product, dried coconut flakes can be pressed to produce coconut milk or oil. This can be accomplished with hydraulic presses or expeller machines.

Filtering and processing: The extracted coconut milk or oil could be filtered and refined to remove contaminants and increase quality.

Packing: The finished coconut goods are packed in containers, bottles, or other packages appropriate for storage and distribution.

What is the best manufacturer of coconut processing plants?

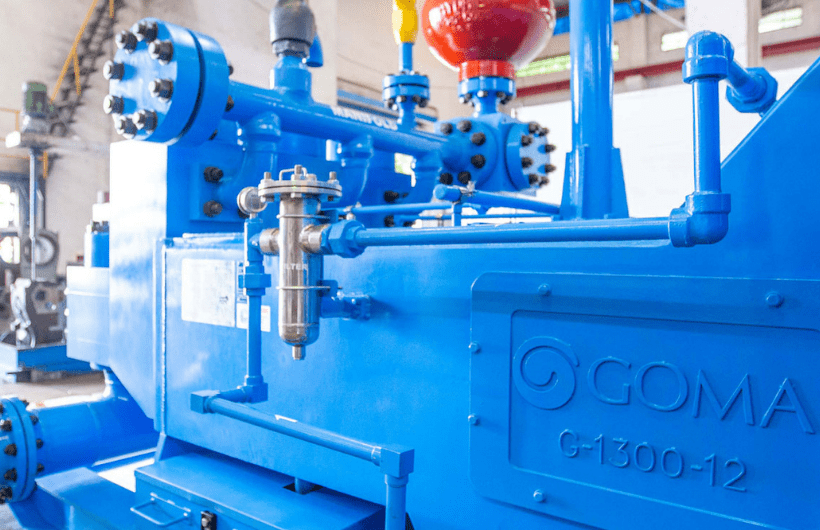

Goma Engineering Private Limited, Mumbai, offers a complete chestnut processing plant, which also includes various milk processing plants right from breaking of the shell to the extraction of water/milk, purification, homogenization, pasteurization, UHT, filling & Canning for producing Tender Coconut Water, Coconut Milk, Virgin Coconut Oil, Coconut Milk Powder, neera, etc.

We are specialized in liquid food processing technology, and their constant R&D to provide personalized solutions ensures that their Customer’s needs are met. Right from concept to commissioning, Goma provides a complete package so that their customers reach their imaginings and objectives.

We have long experience in manufacturing and designing energy-efficient and hygienic coconut processing plants. It has supplied several turnkey projects in the Indian Subcontinent and even overseas.