13 April 2022

How Does Cup Sealing & Cup Filling Machines Works?

The rising level of disposable income on a personal level is the major factor contributing to the cup filling and sealing machine market. As people are getting busier in their professional lives, little time is left for cooking, storing, and preserving food items. There’s a massive growth in Food and Beverage industry and constant innovations are enhancing this particular market for the urban population. Milk and milk products (dairy products) are always in demand owing to their nutritional factors as well as the global food trends and their use in the new-age kitchen. These machines are easy to operate and least failure rate which is one of the reasons for their growing popularity of them.

About cup filling machines:

are widely used in the dairy and food industry for the filling and sealing of curd/yogurt milk, ice cream, water, shrikhand, yogurt, lassi, buttermilk, Greek yogurt, rabri, and many beverages including coconut water, etc.

New development in process technologies and cold chain, rising income, and changing food habits are the factors that accelerate the growth of yogurt, beverages, and ice cream leading to the use of cup filling machines. These cup filling machines are available in both rotary & linear types. The cup sizes range from 50 grams to 500 grams & the machine output ranges from 1200 CPH to 10,000 CPH. The sealing rooms are sterile and a high level of hygiene is maintained, as it is a crucial factor in the industry. Thus, the cup filling and market is growing even more.

Working on cup filling machines

Let us understand how these machines work:

Both rotary and linear cup filling machines are either mechanically operated or pneumatically operated. Pneumatic operated cup filling machines are the first choice of product manufacture because they are simple, easy to use, and energy-efficient as well. Both rotary and stationary cup filling machines are available in semi-automatic as well as automatic types.

Both of the above types have the following stations

- Filling: The filling of the product is by mechanical volumetric dosing with the possibility of hot and cold filling.

- The dosing system is fitted with different kinds of nozzles depending on the viscosity of the product.

- Lid dispensing devices are given for placing the lids.

- Thermo sealing station provided with one sealing head pneumatically driven, timer base, and thermoregulated with safety devices.

- Date printing device on the lids.

- Ejection of the cup from the rotary or linear cup filling machine to the conveyor.

Cup filling machines are also equipped with devices like:

Cup release:

- Filling with, safety devices (no cups, no filling).

- Lid placing, with safety devices ( no cups, no lid).

- Heat sealing, with safety devices ( no cups, no seal).

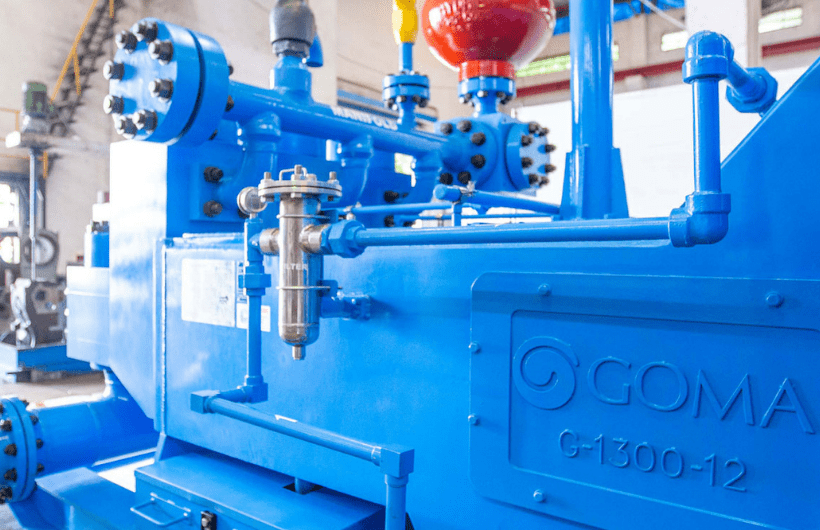

Goma Engineering, Mumbai can offer fully automatic cup filling machines for ice cream, water, shrikhand, Yoghurt, lassi, buttermilk, Greek Yoghurt, and beverages. We have an experience in the manufacturing, design, and installation of energy-efficient and hygienic pneumatically operated cup filling machine for a wide range of products from low to high viscosity. We offer machines with a volume flow range from 50 grams to 500 grams with an output of 600 to 6000 cups per hour.

With the help of our skilled engineers, we have been able to offer an exceptional quality range of Cup Filling & Sealing Machines. There is much more equipment’s in our manufacturing range. These machines are developed using the highest quality and high-caliber technology. Owing to their features such as durability, high performance, and high efficiency these machines are universally demanded by our esteemed clients.