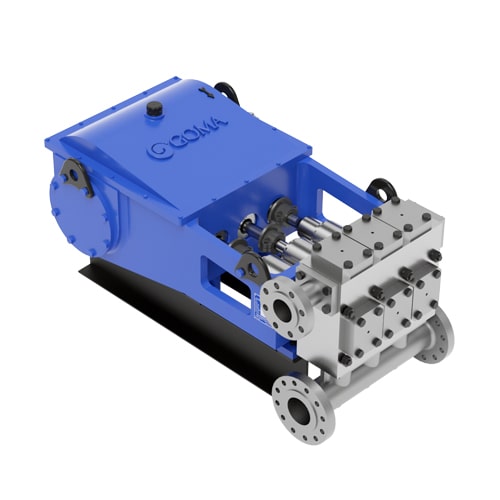

GOMA High Pressure Triplex Plunger Pumps & Systems are the most versatile, time-effective, and economical solution for high pressure cleaning, cutting, removing, descaling, testing, spraying, etc.

The reciprocating plunger pumps and piston pumps are meant for high pressure, low volume (fixed volume) applications and are positive displacement types requiring a positive suction head.

The Goma triplex plunger pumps have an efficiency of more than 90%, which is very high in comparison to centrifugal pumps.

We have almost 15 series of pumps to cater to each of the customer’s requirements for pressure, discharge flow rate, & applications.

We manufacture reciprocating plunger pumps and triplex piston pumps from 1 HP up to 1000 HP (750 KW); pressures up to 20000 PSI (14000 kg/cm3); and flow rates up to 1000 GPM (4000 LPM).

The triplex plunger pumps and triplex piston pumps use a crankshaft mechanism where the rotary motion is converted into a linear reciprocating motion.

In the fluid end of the pump, a fixed volume of liquid is drawn per backward stroke through the suction valve and the same is pushed through the discharge during the forward stroke through the discharge valve.

The suction & discharge valves are non-return types, and the design varies depending on the type of application & liquid to be pumped.

The flow rate of the pump is directly proportional to the RPM (rotations per minute) of the pump, or strokes per minute of the pump.

The Triplex Plunger/Piston Pumps have three plungers reciprocating simultaneously in synchronization 120* apart from each other.

The triplex reciprocating pump has less flow pulsation as compared to single plunger pumps.

Goma pumps are available with various types of fluid end materials depending on the abrasive and corrosive nature of fluid, pressure rating, atmospheric conditions, etc.

By applying sufficient hydraulic horsepower, very high velocities of fluid can be accelerated through a nozzle.

Hydraulic horsepower is equivalent to the product of fluid pressure and the volume delivered. Fluid velocity is proportional to the pressure developed through a nozzle orifice.

The High Pressure Unit consists of the following:

High-Pressure Reciprocating (Simplex/Triplex/Quintuplex) Pump

Prime Mover: Electric Motor / Diesel Engine

Mounting: Base Plate, Trolley / Trailer

Pulley set with belts and guard or coupling with the guard.

Standard Accessories: Pressure Gauge, Pressure Regulating Valve, Safety Valve, Strainer

Cleaning Accessories (Optional)

Alteration in the pressure/volume relationship is possible with the use of interchangeable conversion kits without altering the pump speed, thus maintaining the efficient working of the drive motors. These are available for all pump units.

*T: Triplex reciprocating pump

*TG: Triplex reciprocating pumps with internal gear reduction

*QT: Quintuplex reciprocating pump

NOTE:-

Each pump series has different plunger and piston sizes to accommodate the desired parameters.

The discharge volumes indicated are based on 100% volumetric efficiency with water.

Ratings given are based on nominal speeds and pressures; they may vary with our written approval.

Pumps offered as per API 674 will be governed by speed limits as per standards.