Goma has more than 30 years of experience in over 250 installations of API 674 standards in India & around the world.

The pumps are designed and manufactured according to American Petroleum Institute API 674 standards, specifically to serve the oil & gas industry for their continuous duty process applications.

The pumps are highly apt, robust, and steady, having state-of-the-art sealing technology designed considering every aspect of API 674.

The pressure requirement, liquid properties, and surroundings are kept in view during the selection of the pump material for the specific oil & gas applications upstream, midstream, and downstream.

The pumps are designed in a way to have absolute accuracy even in the most unfavorable conditions.

All API pumps are examined meticulously, and third-party inspections are run as well.

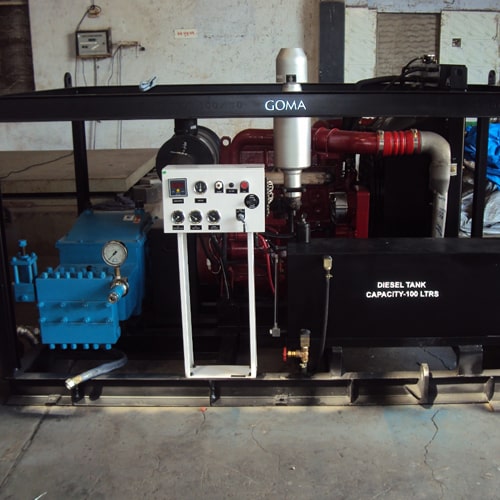

The spare Equipment & accessories are chosen as per API 674 specifications, like filter & self-supporting rigid skids, speed reduction gearbox, suction stabilizers, safety relief, isolation & bypass valves, pressure & temperature transmitters, instrumentation & control monitoring panels, strainers, etc.

Goma pumps are rugged, sturdy, and made in nine different frame sizes, each with a range of plunger sizes.

This helps in choosing the right pump to suit the specific application.

These pumps, though high-pressure, are compact and accessible, with the option of various seals & construction materials.

These pumps come with a variety of plunger-size kit pumps; hence, the user has the flexibility to alter the combination of pressure & flow rate in a definite range.

The quality of our patterns, products, and techniques is approved & endorsed by our extensive quality structure and vast pump facilities.

With our key innovation, continual improvement, R&D, and customer-concentrated approach, we have positioned ourselves at the zenith of cutting-edge pump design, solutions, and prompt customer service.

Many national oil companies from various countries have had a rewarding experience with our products and services.

Design Features:

There is flexibility in the selection of materials as per requirements.

As per the specification, we provide off-shore design and coatings.

As per the customer's specific requirements, provide custom-made solutions, keeping in view API 674/ISO 13710.

For easy movement, three runner skids are given, which also help in vibration arrest.

Cast steel or forged fluid ends are available in various choices to ensure compatibility with the pumping medium.

The crankcase is enclosed completely with improved splash-gravity lubrication, providing stability. A forced feed system is fitted for harsh service.

Heavy duty taper roller Main bearings are rated for continuous duty cycles at maximum design load.

Hardened wearing parts in specially selected components, with anti-friction bearings and bushes at appropriate items, ensure long life.

Fluid-end has flanges on both sides to suit customer piping layout.

Goma conducts various tests on the pumps as per API 674 standards, some of these are optional:

Liquid end hydrostatic pressure tests

Complete performance tests

Bare shaft pump test

NPSH tests

Stress and fatigue test

Mechanical run test

Reliability and pulsation assessment

3D modeling

Vibration tests

Seismic test

Noise test

Strip test